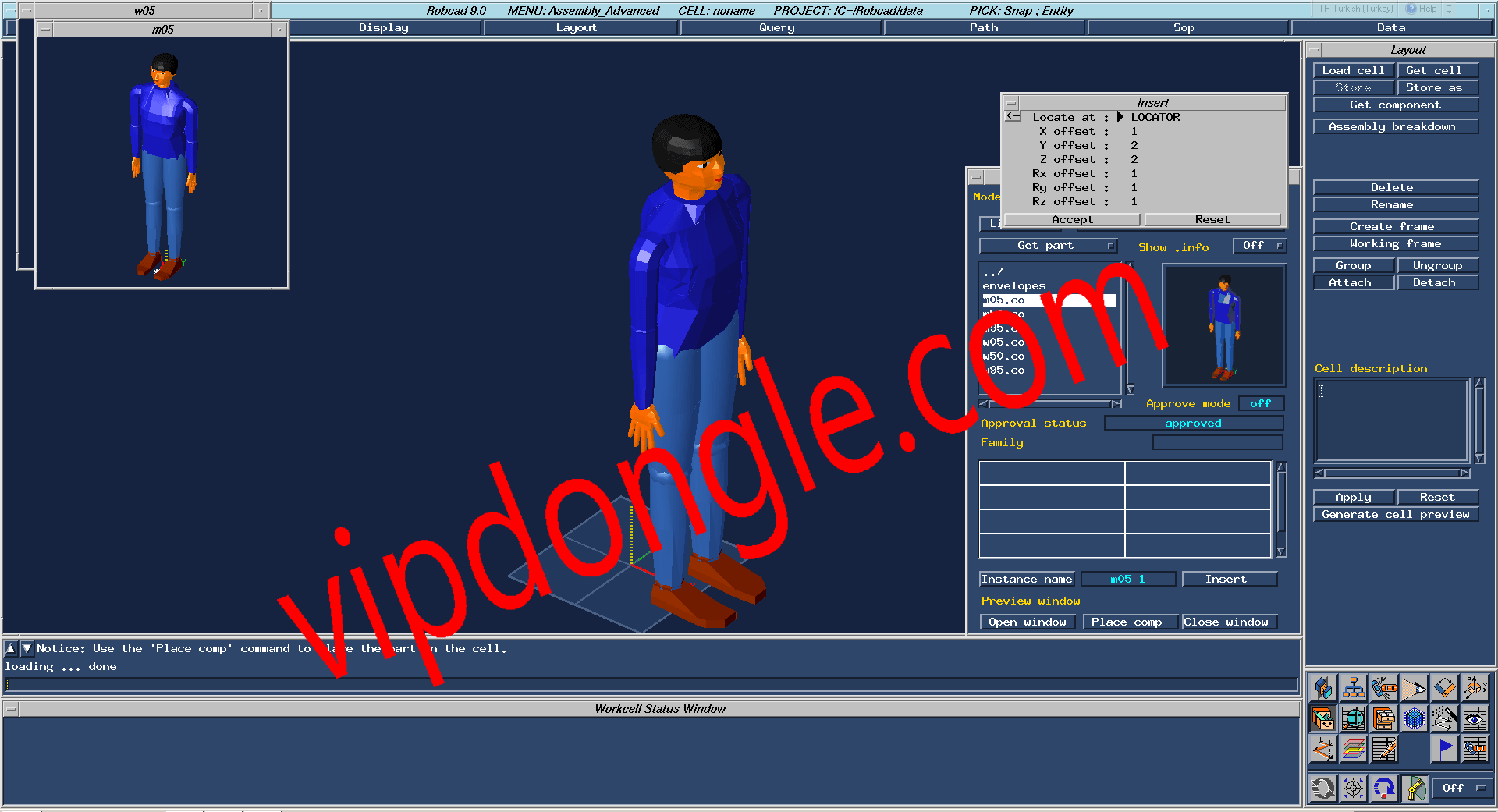

Tecnomatix Robcad Crack

Digital Manufacturing Environment For Robotic Workcell Verification And Off-Line Programming As industries are pressed to meet timing and flexibility within manufacturing systems, there is need to make sure all aspects of the system have been proven-out before costly purchasing and installation decisions take place. With the high cost of automation equipment like Robots, it is necessary to make sure that the equipment is functioning to maximum efficiency and productivity, in order to realize optimal returns on the investment for both new manufacturing systems and mid-cycle changes to existing lines.

Inside folder Siemens Tecnomatix Plant Simulation 15.0, already have crack’s file and instruction how to install Siemens Tecnomatix Plant Simulation 15.0 step by step. I guarantee you can install SSiemens Tecnomatix Plant Simulation 15.0 successfully if you follow that instruction. Tecnomatix Robcad workcell simulation tool allows you to develop, optimize, validate and off-line program robotic and automated manufacturing processes. With this license, students can create models with up to 80 objects.

Milner safe serial numbers. In this video tutorial, viewers learn how to dial open a combination safe lock.

Older, manual methods are no longer sufficient to develop these complex manufacturing systems. Manual methods also require many experts in a non-collaborative workflow, can result in improper installation and drive a variety of costly manufacturing changes. In general, these methods cannot account for all the checks necessary to create efficient manufacturing systems. Tecnomatix Robcad is a workcell simulation tool that provides you the ability to develop, simulate, optimize, validate, and off-line program multi-device robotic and automated manufacturing processes, all in the context of configured product and resource data. These full-action mockups of complete manufacturing cells and systems within a 3D environment provide a platform to optimize processes and calculate cycle times throughout the various stages of the development timeline, from concept through implementation.

As a scalable solution, Robcad fully integrates core technologies and a powerful set of process-specific applications that addresses a wide range of processes, including spot welding, arc welding, laser and water-jet cutting, drilling, riveting and painting.